Those of us involved in cross-functional planning often discover that our carefully aligned, high-level plans lose their usefulness when confronted with real business operations. Lots of organisations frequently struggle with their well-designed monthly Sales and Operations Planning system because, in the short term, suppliers adjust schedules, customers make last-minute changes, and machinery has a funny habit of breaking down every other Friday. This is the moment when Sales and Operations Execution steps in and quietly keeps everything moving.

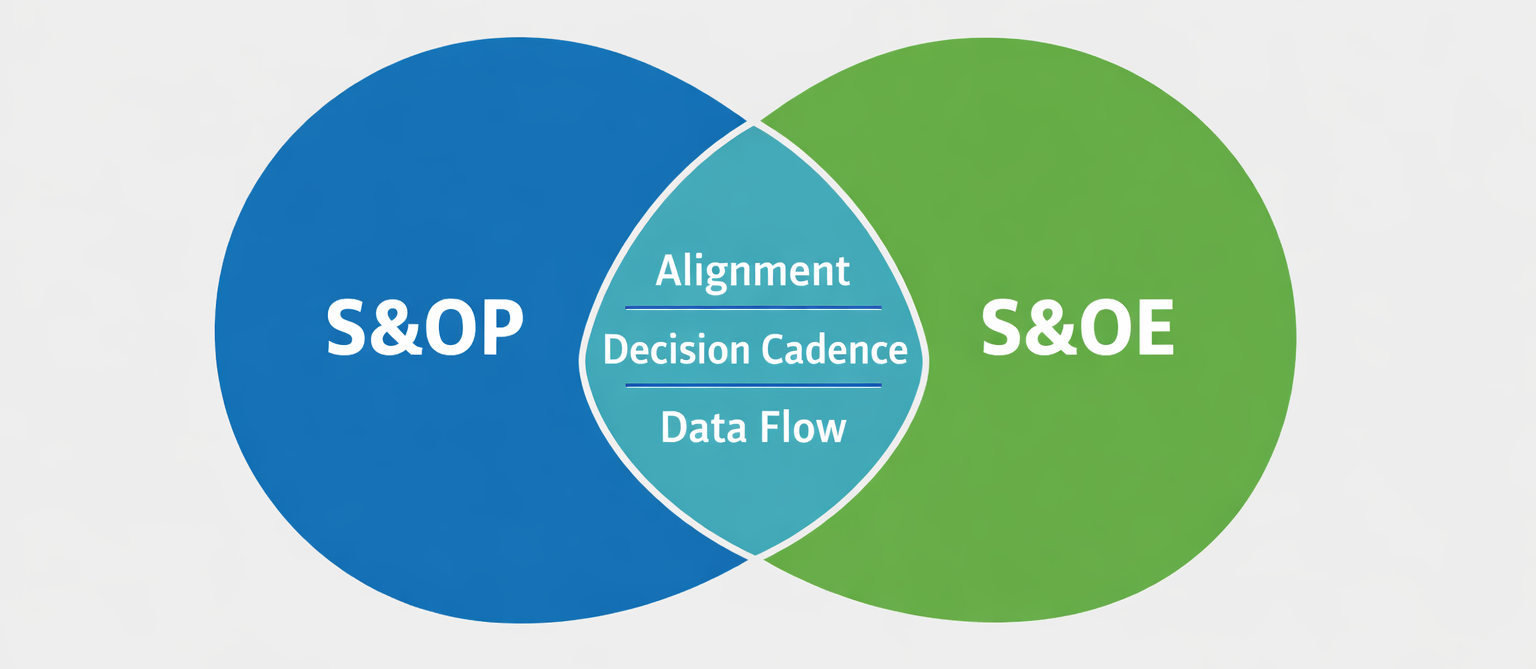

S&OP and S&OE are often mentioned together, but they are far from identical. I like to think of them as two colleagues who work brilliantly side by side. The former prefers predictions, assumptions and long-range scenarios. The latter rolls up their sleeves and focuses on what needs to happen today to keep things moving. Both are essential. Both play different roles. Striking the right balance between them creates a calm and efficient environment that benefits everyone involved.

To understand how they work together, you must first define the boundaries of each process so you can determine what your business truly needs.

S&OP: The Strategic Navigator

Sales and Operations Planning is the core decision-making process that drives strategic choices. It brings together sales, operations, finance, product leaders and others to create a unified view of what the organisation aims to achieve. The process typically looks months and years ahead to set the direction for the business.

S&OP is the forum for long-term discussions. It is where organisations evaluate different options, allocate resources and decide on future investments and areas of focus. What it absolutely is not is a place to argue about which order should be shipped today.

Expecting S&OP to handle everyday operational issues is like asking the board of directors to decide the office lunch order. Important, perhaps, but definitely not strategic.

S&OP creates alignment, reduces surprises and ensures everyone is working from the same map. However, even the best map becomes difficult to follow when the roads are closed, vehicles (or machines!) break down, or customer demand suddenly exceeds all available resources. That is when S&OE takes over.

S&OE: The Tactical First Responder

Sales and Operations Execution is the real-time operator. It works on a much shorter timescale, usually focused on the next few days or weeks. S&OP sets the direction, but S&OE ensures that business operations remain stable through immediate, practical decision-making.

S&OE monitors current orders, supply constraints, live demand and the realities of what is happening on the shop floor. It responds quickly and flexibly, applying corrective actions whenever actual results drift away from planned expectations. Through daily and weekly adjustments, S&OE helps protect the organisation’s long-term targets.

If S&OP is the navigation system, then S&OE is the person at the wheel. Sometimes you need to change direction immediately. Sometimes you have to ignore the Sat Nav entirely because a broken-down lorry has brought the road to a standstill. Either way, S&OE keeps you moving forward.

Where S&OP Stops and S&OE Begins

A simple way to understand the difference is to think of planning versus steering.

- S&OP tells you where you are going.

- S&OE makes sure you actually get there.

Even the strongest S&OP process cannot handle short-term volatility because real business operations rarely follow predicted patterns. S&OE fills that gap by making operational decisions based on real-time information and ensuring continuous operational continuity.

To maintain clarity and structure:

- S&OP makes decisions on a monthly basis.

- S&OE makes decisions on a weekly and sometimes daily basis.

Trying to solve short-term issues in S&OP meetings quickly leads to confusion. Trying to address long-term strategy in S&OE meetings leaves no room to deal with immediate challenges. Keeping the two separate prevents meetings from turning into the organisational equivalent of a warehouse during a stocktake – everyone’s busy, nothing’s flowing, and someone’s tripping over a pallet.

Why Both Processes Matter

Your business needs S&OP because strategic alignment prevents operations from veering off unpredictably, like an Excel with broken formulas. You need S&OE because without disciplined short-term execution, even the clearest long-term strategy can fall apart the moment something unexpected happens, which, in the world of supply chain, is most days of the week.

Together, the two processes make the organisation more agile, better aligned and more resilient. S&OP chooses the destination. S&OE ensures you reach it without getting lost in transit.

A Final Word

S&OP and S&OE are not rivals. They are complementary processes that support one another while maintaining organisational stability, direction and responsiveness. S&OP provides clarity and guidance. S&OE delivers quick thinking and immediate action. Together, they create a smooth and effective system where strategy and execution work side by side.

A well-balanced approach keeps teams aligned, customers satisfied, and stress levels pleasantly manageable. In today’s supply chain environment, that is quite an achievement! If you’d like to see how the right software, combined with a team that’s been in the trenches of S&OP and S&OE, can help you turn plans into confident execution, get in touch with us to start the conversation.